The cable rack is the supporting equipment of modern cables and optical fibers. It was originally introduced by foreign technology and talents, and gradually developed after 30 years. The cable rack products have been widely used in various industries in our country, mainly used for cables and cables. As well as the support and protection of optical fibers, how do engineers make choices when purchasing cable racks?

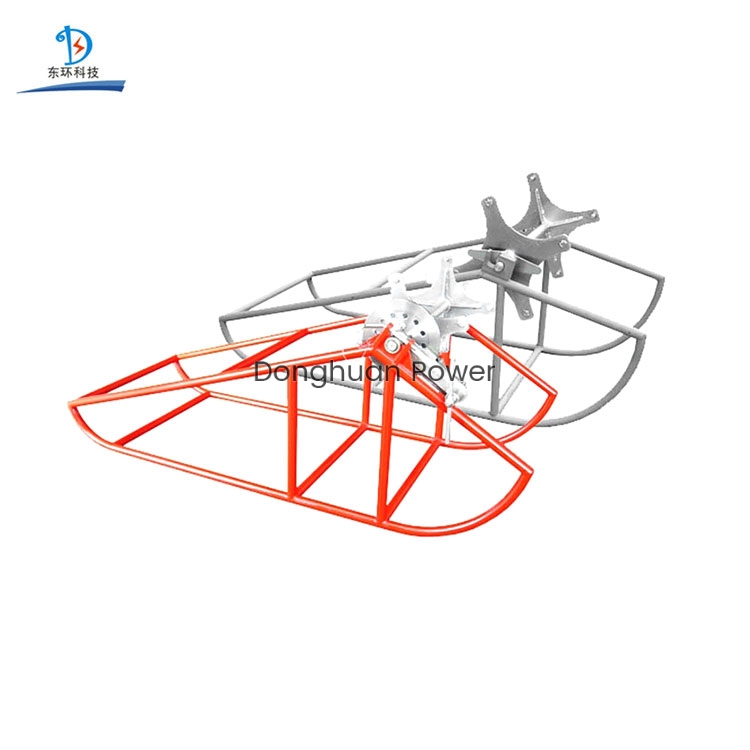

Cable rack

One, choose the material

The current common materials for cable racks include stainless steel, aluminum alloy, glass steel, plastic, color steel, etc. The application scenarios of the cable rack should be tested when choosing which material. Corrosion resistance and durability should be considered for outdoor wiring in coastal cities, so aluminum alloy bridge products are suitable; food factories should prevent damage by rats, ants and insects, and can use fully enclosed trough bridges; underground parking lots and sites requiring fire protection , You can use fireproof plastic sprayed bridge; the wiring of the computer room has very strict requirements on cable interference and load-bearing, so aluminum alloy wire rack and U-shaped steel wire rack have become essential products for modern computer room wiring; production of fiberglass and color steel With low cost and superior performance, it is suitable for the transformation of small factories cable roller.

Cable rack application

The material of the cable rack is varied, and when designing the circuit protection system scheme, measures should be taken according to the actual project.

Second, select the process

The technology of the cable rack includes electro-galvanizing, hot-dip galvanizing, spraying, anodizing, etc. Electro-galvanized bridges generally use the principle of electrolysis to plate a layer of zinc on the surface of the bridges to prevent corrosion. Galvanized trough bridges and galvanized grid bridges are relatively common and used products. . Plastic spraying is generally for fire prevention or aesthetic appearance. The surface of the bridge frame is sprayed with fire-resistant paint to make the bridge frame have fire-retardant properties. The color of the plastic spray can be freely selected. Anodizing can make the bridge more durable.

Three, choose a strong factory

At present, there are more than 300 companies with production qualifications in China. Choosing a cable rack production factory can control costs on the one hand, and customize production according to their actual project requirements.

Cable rack production

Four, about logistics and distribution

Cable rack products are generally calculated by ton, and the production time is generally 3 to 7 days. Choose a reliable factory to produce cable racks, which can be completed on time and shipped on time.

The above are the points that need to be paid attention to when purchasing a cable rack.

English

English Spanish

Spanish +86-574-88852221

+86-574-88852221