Introduction to hydraulic pliers for power tools:

Power tool hydraulic pliers are specialized hydraulic tools for the technical installation of cables and terminals in electrical installation projects. There are integrated, separated, pneumatic, pull-type, etc .;

Classification of hydraulic pliers for power tools: hydraulic pliers are divided into several types, integrated cable hydraulic pliers, mechanical equipment cable connection pliers, steel core cable hydraulic pliers, manual hydraulic pliers, electric hydraulic pliers, etc .;

Hydraulic machine safety saw blade: double-edged 4 sides, higher efficiency; all blades can be replaced; equipped with a growth speed valve, the cut-off time can only be 1.9 seconds; classified for incineration treatment in waste recycling and reuse sites The previous special transformation work; large stones, steel, etc. cannot be cut off, which will destroy the cutting edge.

Second, the basic knowledge of hydraulic pliers for power tools:

1. Maximum torque: It is also the low-torque torque, which refers to the maximum torque of the power torque in the low gear. The rated value is the low-torque torque of 6.0knm. Torque 1.5knm; Low gear speed ratio: The rate of rotation of the hydraulic pliers open transmission gear in low gear, rated low gear speed is 20 pam; High speed ratio: When the high gear of the hydraulic pliers is tightly coupled, the pliers open gear Rotational speed rating high-end speed 85pam; large moving net weight: the net weight of the largest component that is not allowed to be disassembled during transportation, that is, 180kg;

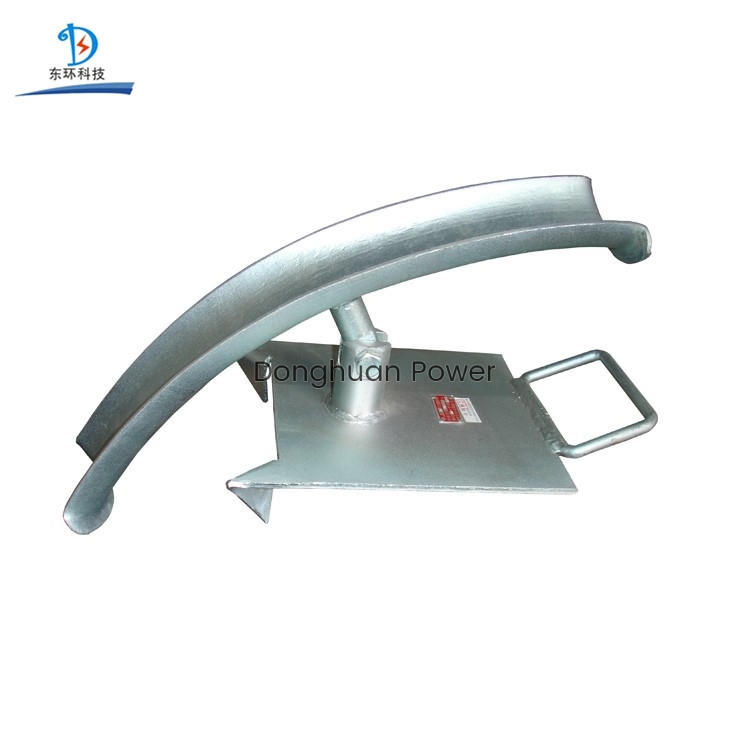

2. The key components of hydraulic pliers for power tools: It consists of a suspension training rod, a tripod, an oil motor, and a front head. The head head includes the open transmission gear, jaw plate frame, and the left and right covers of the open transmission gear. And ramp construction;

3. How much is the total width of the hydraulic piping bite under different torque effects: under different torque effect, hydraulic pliers are not allowed to have deviation when holding the tube. Under the best torque effect, bite When the total width of the print is less than 0.4mm, the total width of the bite print does not exceed 0.8mm; how much is the parallelism of the oil pipe and the core of the clamp head when the hydraulic pliers are turned: When the power clamp is turned, the parallelism of the oil pipe and the core of the clamp head is less than 1.4 mm, there will be deviation from the forum, not holding the tube;

4. How strong is the strength of the hydraulic tool pliers of the power tool, and whether there will be deviations: The strength of the hydraulic pliers will be 60-65 ° Rockwell. If the strength is not reached, the deviation will occur, and the damage of the teeth will be accelerated;

5. How long is the lubrication cycle time of each lubricating position of the hydraulic clamp: The lubrication cycle time of each position is: 1) Opening gears, jaw plates, jaw plate frames, upper rollers, brake system steel plates and friction plates at the lower rollers are relatively opposite. At the speed, fill the car engine oil once in each shift; 2) Fill each nozzle with 15-20 days of unsalted butter; 3) Every three months, remove the orifice plate and fill the gears with grease .

Third, the power tool hydraulic clamp failure and removal methods:

Slip: Improper installation of single and double wheel jaw plates, adjust the position of single and double wheel jaw plates; jaw grooves are enriched with hard solids to eliminate dirt in the jaw grooves; too many teeth are damaged, replace new teeth Disc; the brake torque of the caliper head is too small, and the brake system is moderately tightened; the friction disc is too damaged, replace the friction disc; the caliper body is not level, correct the caliper body; E plate cannot be retracted to negative correlation: transmission The shaft stop pin does not have the middle part of the button shaft. Turn the reset button 180 ° to reset it; the hanging gear is not strong and easy to fall: the clamping force is too small, add an adjustment pad, and moderately increase the working pressure of the elastic yellow;

Remove the baffle plate and inject grease to the surfaces of each transmission gear. How to adjust the limit switch screws on the back of the E plate frame, first when the ∮60, ∮13 oil pipeline is lowered (that is, 2 inches, 2 inches and a half), open the transmission gear The inner jaw plate frame rotates 180 °, that is, after the jade plate frame rotates to the opening, a screwdriver is required to adjust the limit switch screw and the bending machine screw rotation pad so that the rotation pad is not pressed by the limit switch screw and then the limit switch is tightened. Screws and bending machine screws; when lowering the ∮89 and ∮114 oil pipelines (that is, 3 inches, 4 inches), the method is the same as above, just press the rotation pad with the limit switch screws, and then tighten the limit switch screws bending machine screws.

English

English Spanish

Spanish +86-574-88852221

+86-574-88852221