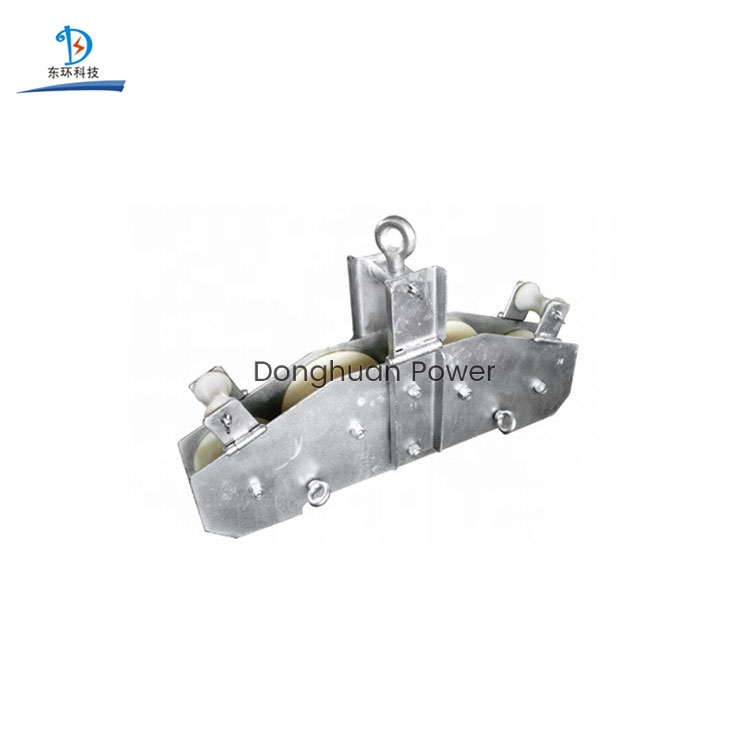

Stringing Blocks come in many varieties, styles, sizes and materials. Most are made of galvanized steel, but others are made from other metals like aluminum and copper. There are also several types of Anti Twist Wire Rope (ATW), which is commonly used in commercial applications. A common use is in the construction of railroad ties, which require an economical way of fabricating these very important ties. The ATW ropes are designed to withstand the high stress of the application because they are so strong and many of them are multi-coated to resist corrosion. Some of the ATW ropes can be very expensive; however, the more commonly used ATW rope is the round end variety.

Dura-Tred polypropylene fiber was used in the construction of stringing blocks. Fiberglass was also used but it proved to be an unsafe material in vibration regions. Now the newest technology is the Anti Twist Wire Rope, which is composed of strands of high quality polypropylene fiber that has been twisted on a shaft, which is then threaded onto standard metal or steel tubing. This type of rope is not only safe for vibration application but it is also very economical.

Dura-Tred fiber was introduced as a material in the late 1970's, which was the first choice of fabricators continually utilized it. They also use this fiber in the manufacturing of standard pulley, cable, stringing blocks and other components. The strands of Dura-Tred are twisted on a shaft and they are threaded onto standard metal tubing. Nylon stringing blocks are constructed using this same technology. The nylon strings also feature an anti-twist feature and a feature that prevent the possibility of strand separation.

These nylon stringing blocks are primarily used in the building of helicopter rotor blades. In addition to this, it is also used in the manufacturing of high speed transportation vehicles and parts for extreme conditions. Since the early 1980's, these stringing blocks have been used in building both light and heavy weight aircrafts and are also utilized in the making of ski equipment. It has also been utilized in the construction of computer generated parts for both the military and commercial industries.

The construction of the nylon stringing blocks consists of interlinking strips that link the base material with a core, which is the concave portion. The interlinking is accomplished by utilizing either heat or mechanical pressure. The blocks are usually coated with a friction material such as nylon to reduce friction and ensure optimum performance. Each of these features provides an optimized performance, which in turn ensures durability. The nylon stringing blocks are often designed with either interchangeable tapered interlocking tabs or code descriptions that allow for the interchangeability of the same blocks.

It is often utilized as the main component in the building of helicopter blades. The construction of the single conductor stringing blocks along with the use of the heat welding technique allows for efficient production of the required wiring. This is in addition to the regular use of the single conductor wire without any coating. Some of the best applications of the single conductor wire stringing blocks are as follows Hot gas turbine blades, bulletproof vests, electric power poles, remote control vehicles, gyro planes, and radio control gimbels. Since the invention of the single conductor wire stringing blocks, various other technological innovations have also been introduced in the field of the electronics industry.

English

English Spanish

Spanish +86-574-88852221

+86-574-88852221